SBS's complete production line system has developed the first production line with an annual output exceeding 10 million m2 in 2010, which has reached the requirements for (Implementation Rules for the Production License of Construction Waterproof membrane ) and has obtained a number of patents. The speed of the assembly line has reached 80 meters / min, and the annual output exceeds 15 million m2. It is currently an advanced equipment with a relatively high production volume in the same industry in China.

In addition to our standard high-performance production lines, we offer tailored engineering solutions to perfectly match your specific production requirements. Comprehensive Turnkey Solutions – Beyond Equipment Customization. To maximize your operational efficiency, we provide end-to-end support covering every stage of production:

‧Precision Formulation Services

‧Tailored SBS/modified asphalt recipes for specific climate/application requirements

‧Proprietary additive packages to enhance membrane properties

‧Verified Material Supply Chain

‧Just-in-time delivery with batch-to-batch consistency guarantees

‧Technical Support. Dedicated engineer hotline

‧Troubleshooting & preventive maintenance programs

‧Installation and production training for professional technicians

We don't just sell machines – we deliver worry-free production ecosystems.

Our polymer membrane equipment produces self-adhesive waterproofing materials using PVC/PE/EVA/ECB/TPO via one-step extrusion with nano-coating. The membranes offer superior waterproofing, flexibility, and instant adhesion, remaining effective at -40°C. Eco-friendly and durable, they outperform traditional asphalt options with better aging resistance and cold-weather performance. The system produces both polymer and asphalt-based membranes with reliable formulations.

Polyurethane Waterproof Coating Production Line, which can produce single-component and two-component polyurethane, adopts negative pressure feeding method, powder does not raise dust, and liquid does not leak. The control part adopts computer control, including production, measurement, information feedback and alarm, and automatically performs grading calculation to ensure that each step is accurately calculated. After the production is completed, the computer performs overall calculation, records relevant data and stores it in the database, completely deviating from manual control The realization of automated unmanned operation.

Features: easy operation, strong running stability, long service life and easy maintenance.

The system is a key part in the production line, using the most advanced CNC high-tech technology at home and abroad. The main components are imported PLC programmable controller, Chinese and English display touch screen, Chinese and English display fault alarm location, fully realizing remote automatic monitoring. Service business lays the foundation for zero-distance service. The design speed is 0-80m / min, and the online length accuracy is 10mm. This machine is a perfect device integrating automatic winding, rolling, counting, cutting, unwinding and packaging. It greatly eliminates the length error and maintenance time. In addition, a coiling system is added at the same time as the take-up operation.

The cuff-type heat shrink packaging machine is a fully automatic high-performance film packaging machine specially designed and developed for the waterproofing industry, with a speed of 8-9 packages per minute. It has a power of about 22-25 kW, making it more energy-efficient.

CNC code library unit, design speed 0 --- 80m / min, each library can code 5 rolls * 6 rolls, 5 rolls * 5 rolls, the conveying distance (3m-6m), the code disc chassis is stored in multiples, can be used by large and medium-sized waterproof membrane enterprises to play a role in energy saving and emission reduction.

Modified Bitumen Environmental Dust Removal Equipment

The ceramic heat storage body is used to store the heat generated when the organic waste gas is decomposed, and the thermal energy stored in the ceramic heat storage body is used to preheat and decompose the untreated organic waste gas, thereby achieving high thermal efficiency. The oxidation temperature is set at 800C to 850 Between ℃, up to 1100 ℃. In the combustion chamber of the high-temperature oxidation system, VOC is oxidized to carbon dioxide and water, and the well releases a lot of heat. The purified exhaust gas can reach the emission standard. The regenerative incineration system is mainly used for occasions with low organic exhaust gas concentration and large exhaust gas volume. It is also very suitable when the organic waste gas contains corrosive substances that are toxic to the catalyst and needs a higher temperature to oxidize a certain odor.

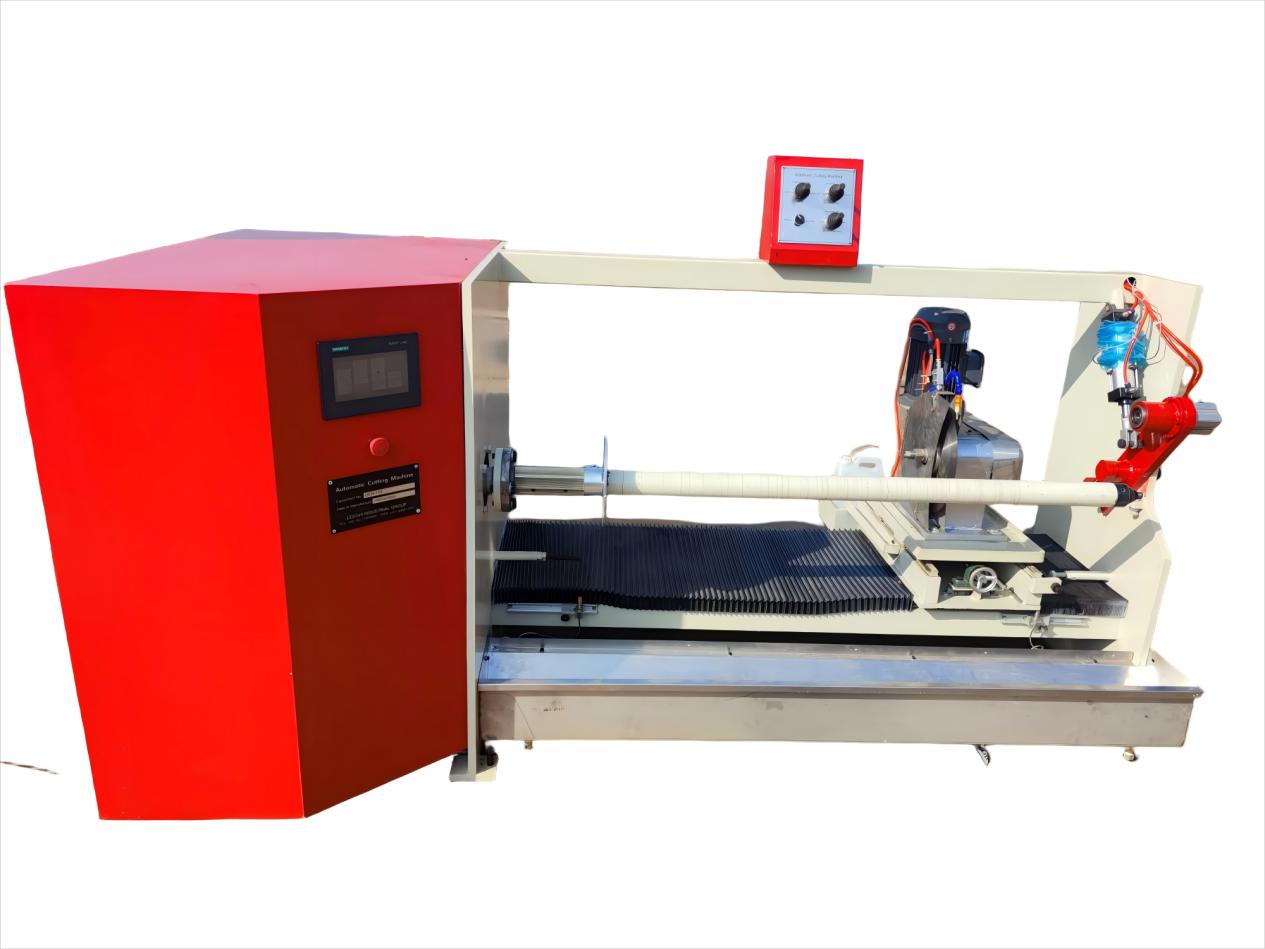

Automatic Cutting Machine

Bagged Bitumen Melter